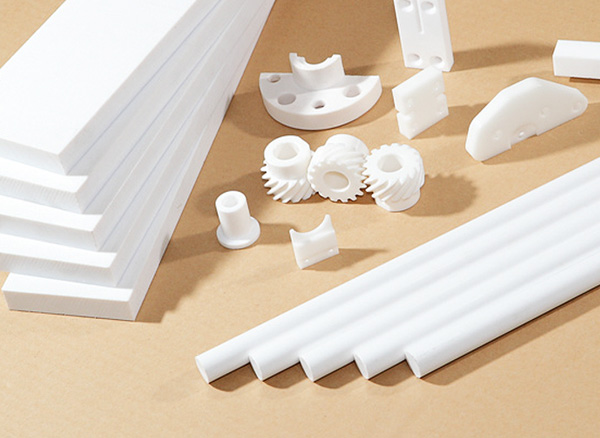

‘AARKAYMID’® HPM – PET : PET is one of the most widely used engineering plastics, together with POM-C and MC-NYLON. Its excellent mechanical properties make it suitable for precision mechanical parts. It provides high tensile and mechanical strength, high hardness and good dimensional stability. Due to its low coefficient of friction, PET is often used for the parts requiring high wear resistance such as wear pads, bearing and bushing, wheels and rollers. PET is also suitable for food processing applications, requiring high chemical resistance and low moisture absorption.